We aim to get the potential of fracture toughness optimised methodologies extensively known by steelmakers, part makers and OEMs, offering a simpler and more cost-efficient solution for measuring the fracture toughness of thin metal sheets

TOUGHSTEEL

Fracture Toughness as a tool to address cracking

In forming and in-service performance Advanced High-Strength Steels

In a nutshell

Dissemination and valorisation of fracture toughness as a material property to rationalise crack-related problems in AHSS

ToughSteel aims to enhance the value and increase stakeholder awareness of Fracture Toughness approach benefits, which has proved to be an effective tool to address crack-related challenges in Advanced High-Strength Steels (AHSS) in car lightweighting and has high replicability in other sheet metal forming applications.

The project is to disseminate to the main actors of the sheet metal forming community the possibility of measuring fracture toughness in thin sheets by means of the Essential Work of Fracture (EWF) and use it to effectively address and solve crack-related phenomena, as edge cracking and to select and develop AHSS with optimised crash performance.

Collection, organisation and analysis of fracture toughness data and publications

Database of fracture toughness of AHSS and steel sheets data

Industrial guideline to describe methodologies of fracture toughness evaluations

Launch of an Open Call to enrol industrial companies as case studies

Organisation of academic and industrial events

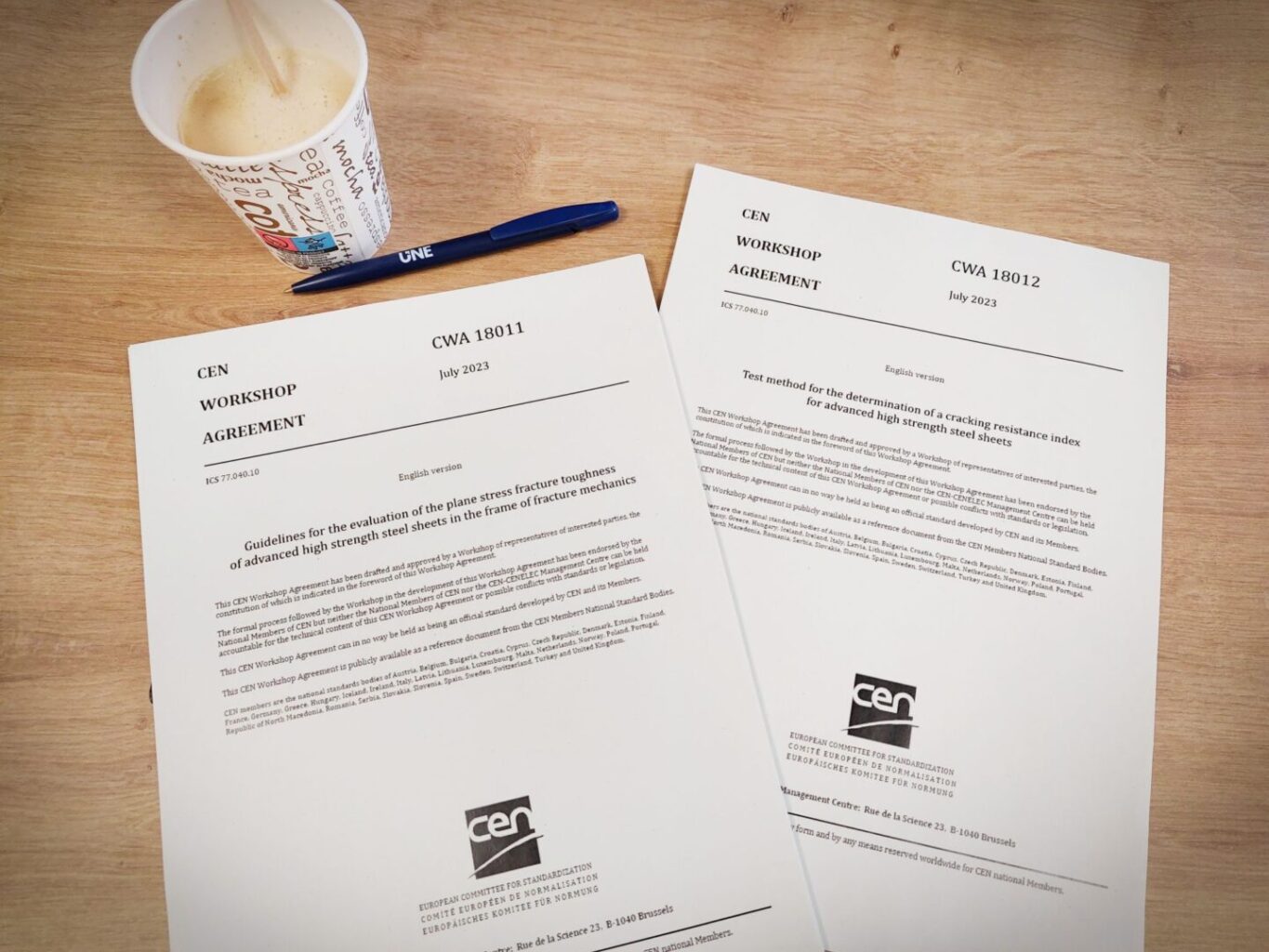

Identification of standards and dissemination in international standardization committees

Stay in touch!

Subscribe to our community of interest to be informed about the latest news and upcoming events organised by ToughSteel.

About

Advanced High-Strength Steels

The need for lighter and stronger material gave rise to the so-called Advanced High-Strength Steels (AHSS). The advanced high strength steels (AHSS) family includes a vast variety of high-performance multiphase steels. These steels are characterised by their complex multiphase microstructures and excellent mechanical properties, which make them especially suitable for structural and safety-related auto body components.

Their higher strength and enhanced impact performance compared to conventional steels allow reducing the vehicle mass while improving the safety of the occupants, which is essential to satisfy the more and more stringent safety and fuel consumption regulations.

From our blog

Project news & events

Upcoming events

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | |

Partners

Our team

ToughSteel interdisciplinary consortium is made up of 8 partners from 4 European countries with technical knowledge on fracture toughness.